Lime Material Introduction

The main component of quicklime is calcium oxide, modern use of mechanized, semi-mechanized vertical kiln and rotary kiln, boiling furnace and other equipment for production.

Quicklime is a commonly used desiccant to remove water vapor by chemical absorption method, especially suitable for iron and steel, medicine, chemical, agricultural soil, desiccant, puffed food, instrumentation, electronic telecommunications, leather, textile and other industries.

Quicklime Powder Making is

Generally Divided into

Coarse powder

0-3mm

Fine powder

20 mesh-400 mesh

Ultrafine powder

400-1250 mesh

Micronized powder

1250 mesh-3250 mesh

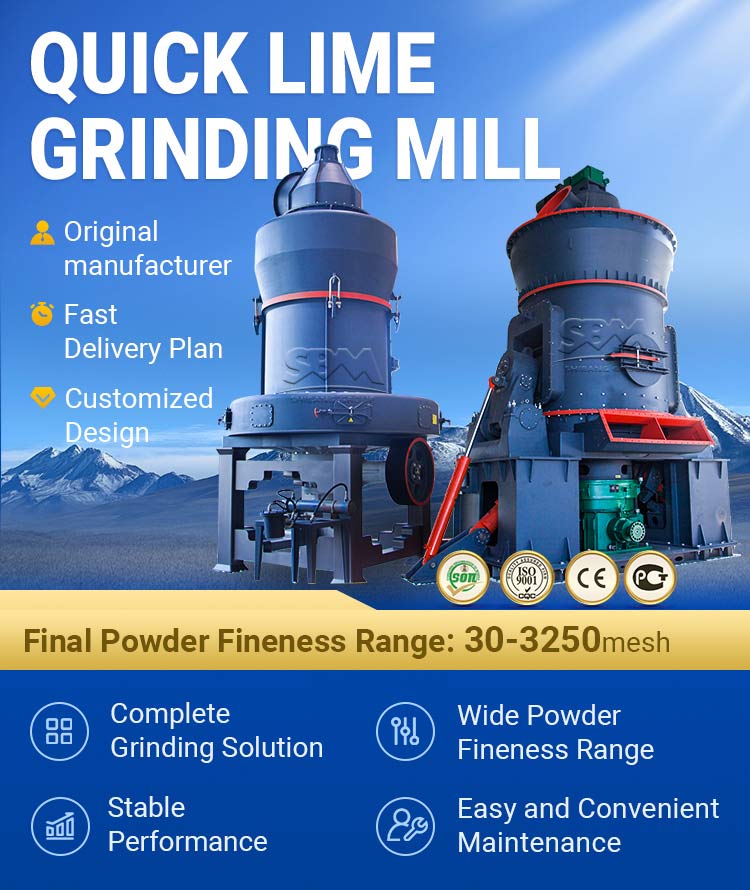

Quicklime Grinding Equipment, Including

The quicklime grinding equipment production line type can be configured according to the order demand for processing quicklime.

Get Solution & Price Right Now!

Leave your information below to get customized

solutions and free quote!